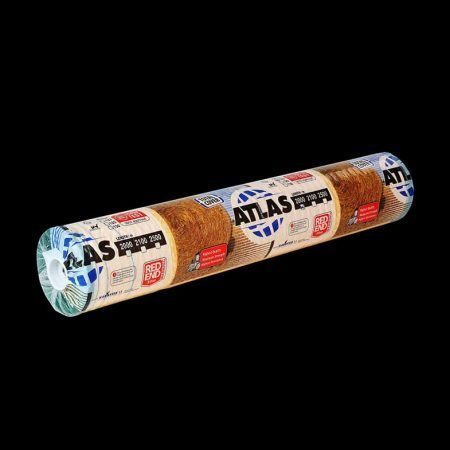

SILOMAX® BLACK & WHITE SILAGE FILM

Winter animal feed is covered and protected by an opaque black and white silage film which is produced in a thickness ranging between 150my and 200my.

PROPERTIES AND APPLICATIONS

Fresh foods intended for animal feed are preserved through their placement in special preservation silo containers, or similar methods, such as a specific method called internationally “ensilage”. The addition of preservatives is essential to guarantee good quality preserved animal feed. Large temperature increases are avoided due to the dual membrane properties since the white coating of the film is located on the top and reflects sun’s rays. Further temperature stabilization is achieved by the black coating of the film at the bottom part.

HOW TEMPERATURE AFFECTS STORED FOOD (SILAGE)

In order for milk enzymes to be produced, it is necessary to achieve an optimum temperature. The color of the crop is a good indication to the farmer for the calculation of the temperature. The normal temperature of stored products should provide it with a light green or yellow color and should exude a pleasant smell like vinegar. Where stored food exudes strong odor and the color is dark green, it is obvious that the storing of feed was performed under low temperature conditions.

Ideally, the crop should have a strong acidic taste with Ph values less than 4.5 and should be hard to the touch. When the product is found to be of brown or black color with an odor of bad straw or burnt sugar, this is an indication that the product storage process for preservation was performed at very high temperatures.

Tips for preserving animal feed in “silo” type structures

The following guidelines should be taken into account to improve the preservation of fodder.

- Crops must be clean prior to storage.

- Silo filling must be uninterrupted and must be completed as soon as possible.

- The mass of the product to be preserved in the silo, must have a uniform composition.

- The type of product to be stored shall determine the use of the right preservative.

- Animal feeding should be performed when the stored product is at its peak nutritional value.

- The silo (specialists fodder storage areas) must be hermetically sealed.

- The silos should be located in an area which is subject to minimum solar heat influences.

- The feed from the silos must be distributed to the animals after being cut and divided into small pieces.

SILOMAX® BLACK & WHITE SILAGE FILM

Dimensions

8m x 30m

10m x 30m

12m x 30m

12m x 40m

14m x 30m

14m x 40m

16m x 30m

16m x 40m